In the realm of construction and infrastructure, lies a subtle yet pivotal ingredient that binds the very foundation of our human-made marvels – the harmonious amalgamation of earth's resources. This incisive compendium shall navigate you through the artistry entailed in combining the building blocks of human progress through intricate knowledge and meticulous expertise.

Within the pages that follow, we embark upon an expedition to decode the elusive process of unifying granular matter into the resilient substance known as concrete. Prepare to be enthralled as we unlock the secrets residing within the symphony of cementitious materials and their synergistic union with aggregates, water, and additives.

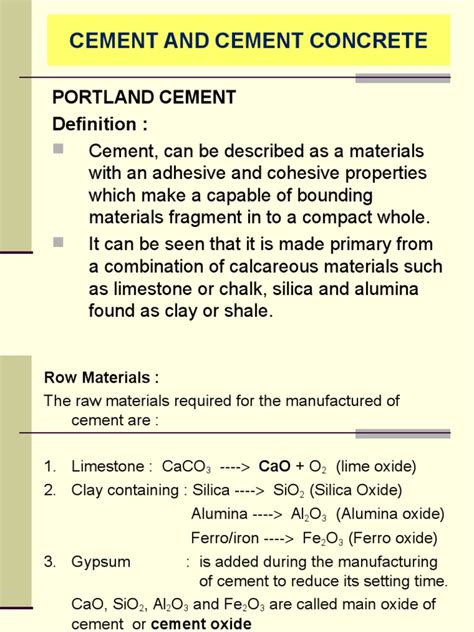

Our unparalleled odyssey commences with a comprehensive overview – a canvas showcasing the versatility and possibilities brought forth by the graceful dance of binding agents. Here, we shall decipher the significance of manipulating chemical reactions and harnessing the colossal strengths of various cement types. Delve deep into the nuances of Portland cement, fly ash, silica fume, and a myriad of alternatives that lend their distinctive charm to every architectural masterpiece they contribute to.

As you delve further, the journey unfolds to unravel the mysteries of the aggregate arena. Discover the unparalleled beauty of crushed stone, gravel, sand, and their indispensability in achieving the desired structural integrity. Learn to decipher their intricate gradations, diverse geological origins, and the exquisite artistry behind their meticulous selection for each unique project. Unlock the hidden potential in the seemingly ordinary pebbles that grace our footpaths and soaring skyscrapers alike.

But wait – there's more to this ethereal symphony than meets the eye. Prepare to be immersed in the liquid poetry that transcends time and space. Through the judicious addition of water and a delicate blend of chemical admixtures, we uncover the secrets behind achieving optimal workability, strength, and durability. Traverse the pathways of hydration and discover the transformative alchemy that propels concrete from its liquid infancy to its solid maturity.

Come forth, fellow seekers of knowledge, as we embark upon a holistic exploration of the enchanting art we call concrete mixing. Let us unravel the ethereal beauty concealed within these seemingly ordinary materials and forge a path towards turning dreams into tangible reality – one exquisite blend at a time.

Understanding the Fundamentals of Cement Blending

In this section, we will delve into the essential concepts and principles that form the foundation of cement mixing. By gaining a thorough understanding of these basics, you will acquire the knowledge and skills necessary to successfully blend cement for various construction projects.

Composition: Cement is a versatile construction material composed of different elements that work together to create a solid and durable end product. Understanding the composition of cement will enable you to grasp how each ingredient contributes to its specific properties.

Proportions: The correct proportions of cement, water, and other possible additives are crucial for achieving the desired consistency and strength in the mixture. Learning how to measure and adjust these proportions accurately will greatly impact the quality of your cement blend.

Mixing Techniques: Mixing cement involves several techniques, ranging from manual blending with shovels to using mechanical mixers. Understanding these techniques and their advantages will allow you to choose the most suitable method for your specific project.

Setting and Curing: Cement goes through a process of setting and curing after it is mixed. Understanding the factors that affect these processes, such as temperature and humidity, will help you ensure the optimal conditions for achieving maximum strength and durability in your cement blend.

Common Mistakes: Finally, we will highlight common mistakes that can occur during cement mixing and provide guidance on how to avoid them. By being aware of these potential pitfalls, you can save time, effort, and money in your cement blending endeavors.

By delving into these fundamentals, you will gain a solid foundation in cement mixing, empowering you to create blends that meet the highest standards of quality and performance in construction projects.

Essential Tools for Achieving Success in Cement Blending

In order to create a successful blend of cement, there are several indispensable tools that every aspiring cement mixer must have in their arsenal. These tools are crucial for ensuring the proper consistency and strength of the final mixture, allowing for a smooth and efficient construction process.

| Tool | Description |

|---|---|

| Mixing Container | A sturdy container, such as a wheelbarrow or a cement mixer, is essential for holding the cement, aggregates, and water during the blending process. |

| Measuring Tools | Accurate measuring tools, such as a shovel or a scoop, are necessary for precisely measuring the amounts of cement, aggregates, and water needed for the desired mixture. |

| Mixing Tool | A mixing tool, such as a hoe or a mixing paddle, is essential for thoroughly combining the cement, aggregates, and water to achieve a uniform and consistent mixture. |

| Protective Gear | Wearing appropriate protective gear, such as gloves and goggles, is imperative to ensure personal safety during the cement mixing process. |

| Storage Containers | Proper storage containers, such as buckets or sealable bags, are necessary for storing excess cement mixture for future use, preventing wastage and maintaining the mixture's quality. |

| Cleaning Supplies | Having cleaning supplies, such as a hose or a bucket of water, is crucial for cleaning the mixing tools and the mixing area after the cement blending process, helping to maintain cleanliness and prevent the cement from hardening. |

By having these essential tools at hand, cement mixers can ensure a successful blending process, resulting in a high-quality cement mixture that is ready for use in construction projects of various scales and complexities. Remember, the right tools can make all the difference in achieving the desired outcome and ensuring the longevity and durability of the structures being built.

Choosing the Appropriate Cement for Your Project

When embarking on any construction or renovation project, it is crucial to select the right type of cement. The choice of cement is integral to the success of your project, as it determines the overall durability and strength of the structure. Various factors such as the type of construction, environmental conditions, and desired finish must be taken into consideration while making this decision.

Here are some key points to keep in mind when deciding the appropriate cement for your project:

- Type of Construction: Different types of construction require different types of cement. For example, if you are working on a residential project such as building a house or a driveway, Portland cement is commonly used due to its high strength. On the other hand, for projects like dams or bridges that require enhanced strength and resistance to chemical reactions, special types of cement like Sulphate Resistant Cement or Pozzolanic Cement may be more suitable.

- Environmental Conditions: The climate and environmental conditions of the project site play a crucial role in choosing the appropriate cement. For areas with extreme weather conditions, such as areas prone to high temperatures or those with constant exposure to seawater, selecting a cement that is resistant to such conditions is essential to ensure the longevity of the structure.

- Desired Finish: If aesthetics are a significant consideration for your project, it is crucial to choose a cement that can provide the desired finish. Quick-setting cement, for instance, is ideal for projects that require fast completion, while white cement can be used for decorative purposes to achieve a smooth and clean appearance.

- Workability: The workability or the ease with which cement can be mixed, placed, and compacted should also be considered. Depending on the type of project, certain cement types may offer better workability, making them easier to handle, shape, and finish.

- Budget: Finally, cost is also an important factor to consider when choosing cement for your project. Some specialized types of cement may come with a higher price tag, so it is crucial to strike a balance between quality and affordability.

By carefully considering these factors and consulting with a professional, you can ensure that you choose the most suitable cement for your project's specific requirements. The right choice will not only guarantee the durability and strength of your structure but also contribute to the overall success of your construction endeavor.

Step-by-Step Guide: Proper Cement Mixing

To ensure the successful formation of a sturdy and long-lasting structure, it is crucial to properly mix cement. This step-by-step guide provides detailed instructions on how to achieve the ideal cement mixture, enhancing the overall strength and durability of your construction project.

Materials:

| - Cement |

| - Water |

| - Sand |

| - Gravel |

Step 1: Measuring the Ingredients

In order to maintain consistency and ensure an accurate mix, it is necessary to measure the precise amounts of each ingredient. Use a reliable measuring tool for the cement, sand, and gravel. Additionally, consider the optimum water-to-cement ratio to achieve the desired strength.

Step 2: Preparation

Prior to mixing, it is important to gather all the necessary equipment and ensure a clean and dry working area. The tools required may consist of a mixing container, a shovel, and a water source. Clear the designated area to prevent any contaminants from interfering with the mixture.

Step 3: Mixing Process

Begin by pouring the appropriate amount of cement into the mixing container. Gradually add the sand and gravel, ensuring uniform distribution throughout the mixture. Use the shovel to blend the dry ingredients thoroughly.

Step 4: Adding Water

Pour water into the mixture gradually. Avoid adding excessive water, as this can weaken the cement and compromise its strength. Continuously mix the ingredients while gradually incorporating the water until the mixture reaches the desired consistency.

Step 5: Achieving the Ideal Consistency

Proper mixing will result in a smooth and homogenous mixture with an ideal consistency. The cement should be able to hold its shape when formed into a ball and not appear dry or slushy. Adjust the water amount if necessary to achieve the perfect balance.

Step 6: Final Inspection

Once the mixture is thoroughly blended and reaches the desired consistency, take a moment to examine the resulting mixture. Ensure there are no dry pockets and that all the ingredients are evenly distributed. The mixture is now ready for application in your construction project.

By following these step-by-step instructions and maintaining attention to detail throughout the process, you can confidently mix cement and achieve a high-quality mixture, setting the foundation for a successful construction endeavor.

Tips and Tricks for Achieving the Perfect Cement Consistency

In this section, we will explore various tips and tricks that can help you achieve the ideal consistency when working with cement. Finding the right balance of water and cement is crucial to ensure optimal strength, durability, and workability of the final product.

1. Gradually Add Water

When mixing cement, it is important to add water gradually rather than all at once. This allows for better control over the consistency and helps prevent the mixture from becoming too runny. Add water in small increments and mix thoroughly before adding more, until you reach the desired consistency.

2. Consistency Test

Performing a consistency test is an effective way to determine whether your cement mixture has reached the desired consistency. The slump test is a common method used to measure the workability of concrete. The mixture should hold its shape when molded into a cone, but still be pliable enough to allow for easy leveling and finishing.

3. Use a Mixing Ratio Reference

A mixing ratio reference is an essential tool that can guide you in achieving the perfect cement consistency. It provides recommended ratios of cement to water based on the type of project and desired outcome. Following these ratios ensures consistency and helps avoid common issues such as weak or overly stiff mixtures.

4. Adjustments for Weather Conditions

Weather conditions can greatly impact the consistency of your cement mixture. In hot and dry climates, water evaporates quickly, making the mixture dry and difficult to work with. In colder temperatures, the mixture may take longer to set and achieve proper strength. Make necessary adjustments to the water content and mixing time to account for these environmental factors.

5. Use High-Quality Materials

The quality of the cement and other materials used can greatly affect the consistency of the mixture. Using high-quality cement and aggregates ensures better workability and overall durability of the final product. Invest in reputable brands and products to achieve consistent and reliable results.

6. Proper Mixing Technique

Lastly, the way you mix the cement plays a crucial role in achieving the perfect consistency. Use a sturdy mixing container, such as a wheelbarrow, and a reliable mixing tool, such as a hoe or a mixing paddle attached to a drill. Mix in a circular motion, ensuring all materials are evenly distributed and thoroughly incorporated.

| Tips for Achieving Perfect Cement Consistency |

|---|

| Gradually add water |

| Perform a consistency test |

| Use a mixing ratio reference |

| Make adjustments for weather conditions |

| Use high-quality materials |

| Follow proper mixing technique |

Common Errors to Avoid When Mixing Concrete

When it comes to creating the perfect concrete mixture, it's crucial to avoid certain common mistakes that can compromise the strength, durability, and overall quality of your project. By understanding and avoiding these errors, you can ensure a successful and long-lasting result.

- Incorrect Water-to-Cement Ratio: One of the most common mistakes is not measuring the water and cement accurately. A proper water-to-cement ratio is essential for achieving the desired strength and consistency of the concrete. Too much or too little water can lead to weak or brittle concrete.

- Poor Mixing Techniques: Inadequate mixing can result in an uneven distribution of cement, aggregates, and water. It's important to mix thoroughly to ensure that all components are properly combined. Neglecting this step can lead to weak spots, lower strength, and reduced durability.

- Ignoring Mixing Time: Cement requires sufficient time to fully hydrate and cure. Failing to mix the concrete for the recommended amount of time can result in a weak and unstable structure. Following the recommended mixing time is crucial for achieving the desired strength and durability.

- Inconsistent Mixing Procedures: Inconsistencies in the mixing process, such as using different tools or techniques, can lead to variations in the quality of the concrete. It's essential to follow a consistent mixing procedure to ensure consistent results throughout the project.

- Improper Use of Additives: While additives can enhance certain properties of concrete, they can also negatively affect its performance if used incorrectly. It's important to carefully follow the instructions provided by the manufacturer and avoid excessive or improper use of additives.

- Inadequate Curing: Proper curing is crucial for cement to reach its maximum strength and durability. Neglecting or shortening the curing process can result in weaker and less stable concrete. It's essential to follow the recommended curing procedures, such as maintaining moisture levels and protecting the concrete from extreme temperatures.

By being aware of these common mistakes and taking the necessary precautions, you can ensure a successful mixing process that will lead to high-quality concrete. Remember, attention to detail and following proper guidelines is key to achieving durable and long-lasting results.

Safety Measures for Cement Mixing

Ensuring safety during the process of combining cement materials requires adherence to strict precautions to prevent potential risks and accidents. This section will outline important safety measures that must be followed for a secure cement mixing experience.

1. Protective Gear: When working with cement, it is imperative to wear appropriate protective gear to safeguard oneself. This includes safety goggles, gloves, a dust mask or respirator, and sturdy work boots to protect against chemical splashes, dust inhalation, and foot injuries.

2. Ventilation: Adequate ventilation is crucial while mixing cement, as the process can release harmful dust particles and fumes. Working in a well-ventilated area or using exhaust fans or open windows can help minimize exposure to these hazards.

3. Handling Cement Bags: When lifting cement bags, utilize proper lifting techniques to avoid strains or injuries. Never twist your body while lifting or carrying heavy loads; instead, use your legs and keep your back straight. It is also advisable to wear a back support belt for added safety.

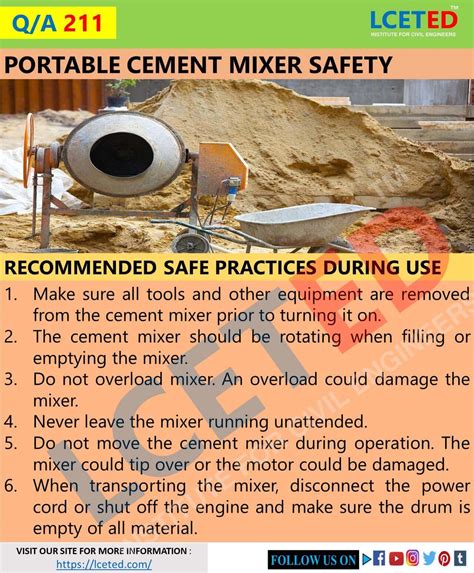

4. Mixing Tools: Ensure that the mixing tools, such as a concrete mixer or shovel, are in good condition and suitable for the task at hand. Check for any cracks or defects that may compromise their functionality or pose a risk during use.

| Safety Precautions | Description |

|---|---|

| 5. Working in a Well-Lit Area | Proper lighting is essential to accurately assess the cement mixing process and identify potential hazards. |

| 6. Avoiding Contact with Skin and Eyes | Cement can cause skin irritation and chemical burns. In case of contact with the skin or eyes, wash immediately with plenty of water and seek medical attention if necessary. |

| 7. Fire Safety | As a safety precaution, it is vital to keep extinguishers or a bucket of water nearby in case of fire caused by flammable materials. |

| 8. Clean-Up Process | Once the cement mixing is complete, proper clean-up procedures should be followed to minimize the risk of slips, falls, or other accidents. |

| 9. Instruction and Training | Prior to starting any cement mixing project, it is crucial to receive proper instructions and training on handling cement materials and operating machinery. |

By incorporating these safety precautions into your cement mixing routine, you can mitigate potential hazards and ensure a safer working environment for yourself and others involved in the process.

Finding Inspiration: Incredible DIY Cement Projects

Unleash your creativity and explore the world of DIY cement projects that will leave you amazed and inspired. With a little bit of imagination and a commitment to experimentation, you can transform ordinary cement into extraordinary works of art.

Discover the boundless possibilities of creating unique home decor, stunning outdoor features, and functional furniture using cement as your medium. From elegant planters and contemporary candle holders to sleek countertops and statement wall art, there is no limit to what you can achieve with this versatile material.

Get inspired by browsing through a curated collection of awe-inspiring DIY cement projects from talented craftsmen and artisans. Explore innovative techniques, such as molding, casting, and sculpting, that will allow you to bring your visionary concepts to life.

- Create mesmerizing geometric-shaped cement planters that add a modern touch to any space.

- Learn how to make personalized cement stepping stones that make for unique and memorable gifts.

- Discover the art of creating intricate cement sculptures that showcase your artistic prowess.

- Experiment with pigments and additives to achieve captivating colors and textures in your cement creations.

- Master the art of concrete casting to design custom-made furniture pieces that perfectly complement your interior.

- Explore the world of minimalistic cement wall art that adds a touch of sophistication to any room.

Whether you are a seasoned DIY enthusiast or a beginner looking for a new hobby, these DIY cement projects will ignite your passion for craftsmanship and inspire you to embark on your own creative journey. Elevate your home decor and channel your inner artist by unlocking the endless possibilities that cement has to offer.

FAQ

What equipment do I need to mix cement?

To mix cement, you will need a few key pieces of equipment. First, you will need a cement mixer, which is a machine designed specifically for mixing cement. Additionally, you will need a wheelbarrow or a large bucket to transport the mixed cement. Other useful tools include a shovel or a hoe for mixing the cement, a spirit level for ensuring a level surface, and protective gear such as gloves and goggles.

What type of cement should I use?

The type of cement you should use will depend on the specific project you are working on. There are various types of cement available, such as Portland cement, masonry cement, and rapid-setting cement. Portland cement is the most common type and is suitable for general construction purposes. Masonry cement is specifically designed for use with bricks or blocks, while rapid-setting cement is ideal for projects that require quick drying. It is best to consult with a professional or refer to the project guidelines to determine the most suitable cement type.

How do I properly mix cement?

Properly mixing cement involves a few essential steps. First, you will need to determine the correct ratio of cement to water. This ratio will vary depending on the type of cement being used and the desired consistency. Generally, a ratio of one part cement to three parts water is a good starting point. Next, add the cement to the mixing container and slowly incorporate the water while stirring. It is crucial to mix thoroughly until the consistency is smooth and free of lumps. Be sure to follow the manufacturer's instructions and guidelines to ensure proper mixing.

Are there any safety precautions I should take while working with cement?

Working with cement can involve certain safety risks, so it is important to take proper precautions. Firstly, always wear protective gear such as gloves, goggles, and a dust mask to protect yourself from any potential hazards. When mixing cement, work in a well-ventilated area to avoid inhaling dust particles. It is also important to be cautious when lifting heavy bags of cement and when operating machinery such as cement mixers. Lastly, be mindful of the curing time of the cement and avoid stepping on or disturbing it until it has fully hardened to prevent injuries.