In the world of craftsmanship, there is an art form that transcends simplicity and ignites the imagination of woodworking enthusiasts. It involves transforming raw chunks of nature into exquisite pieces with surfaces that emanate an unparalleled aesthetic appeal. This captivating process, often referred to as the pursuit of flawlessly polished timber, hides numerous remarkable techniques and expertise that have been refined over centuries.

Behind these remarkable creations lies a world of patience, precision, and a profound understanding of the wood's intricate nature. To unravel the enigma surrounding the crafting of impeccably sanded wood, one must delve into the realm of specialized tools and the secrets of the experts who master this treasured art. From the choice of sandpaper grit to the optimal sanding techniques, an uncharted territory invariably emerges, waiting to be explored.

Yet, in the realm of woodworking, mastering the art of sanding wood is more than just a mere mechanical process. It is an art that requires one to embrace both the practical and artistic aspects of the craft. The artistry lies within the ability to harmonize the wood's inherent beauty with the individual artisan's vision. It is the dexterous touch that effortlessly blends the depth and character of the timber with the finesse of a master's stroke. It is this harmonious union that transcends the realm of mere timber and transforms it into an emblem of craftsmanship and sophistication.

Mastering the Art of Achieving flawlessly smooth and polished Wooden Surfaces

Are you longing for the day when your wooden surfaces boast a sleek and flawless finish? Look no further, as this section will explore the secrets to achieving expert-level sanding! Discover the tips and techniques to transform rough and uneven wood into a masterpiece.

- Unleash the Potential of your Sandpaper

- Optimal Tools for the Job

- The Magic of Sanding Patterns

- Filling the Gaps: Choosing the Right Wood Filler

- Understanding the Importance of Sanding Grits

- A Finishing Touch: The Role of Sealants

- Tackling Common Sanding Issues

- Polishing for Perfection: Bringing Out the Natural Beauty of Wood

In this section, we delve into the art of sanding wood and provide invaluable insights into crafting flawlessly smooth surfaces. From choosing the right sandpaper to understanding the crucial role of sanding patterns, every step towards achieving perfection is explored. Furthermore, we address common challenges faced during sanding and provide practical solutions to make your journey towards the ultimate wooden finish as effortless as possible. Get ready to unveil the hidden beauty of your wooden treasures!

Choosing the Ideal Sandpaper Grit for Your Woodworking Project

In order to achieve the desired smoothness and finish for your woodworking project, it is crucial to choose the right sandpaper grit. The correct grit selection will depend on various factors such as the type of wood, the condition of the surface, and the desired level of smoothness. By understanding the different grit options and their corresponding uses, you can ensure a successful sanding process that leads to impeccable results.

Coarse Grits: When starting a woodworking project, it is often necessary to remove rough imperfections or existing finishes. Coarse grits, typically ranging from 40 to 80, are the ideal choice for this initial sanding stage. They efficiently remove paint, varnish, or layers of wood, preparing the surface for further refinement.

Medium Grits: Once the initial sanding is complete, medium grits, typically between 80 and 120, take over. These grits facilitate the removal of any remaining imperfections, ensuring a more even and consistent surface. Medium grits are also useful for shaping the wood and smoothing out rough edges, providing a solid foundation for the final finish.

Fine Grits: As the woodworking project moves towards its final stages, fine grits ranging from 120 to 220 come into play. These grits are designed to refine the wood's surface, providing a smoother and more polished look. The fine grits help to eliminate any visible scratches or marks left by the previous sanding stages, creating a flawless finish.

Extra-Fine Grits: For projects that require an exceptionally smooth and refined surface, extra-fine grits, typically above 220, are the ultimate choice. These grits are ideal for achieving a mirror-like finish or when working with delicate woods that are prone to damage. The extra-fine grits produce a surface that is ready for staining, painting, or applying a clear coat for enhanced durability.

When selecting sandpaper grits, it's important to remember that each woodworking project may require different combinations of grits depending on the desired outcome. It is recommended to start with a coarser grit and progressively work towards finer grits to achieve the desired level of smoothness. Additionally, using sandpaper with higher grit numbers does not necessarily mean better results; it is crucial to tailor the grit selection to each specific task to ensure the best possible finish.

By understanding the diverse range of sandpaper grits and their respective uses, you can confidently choose the appropriate grits to achieve the desired smoothness and finish for your woodworking masterpiece.

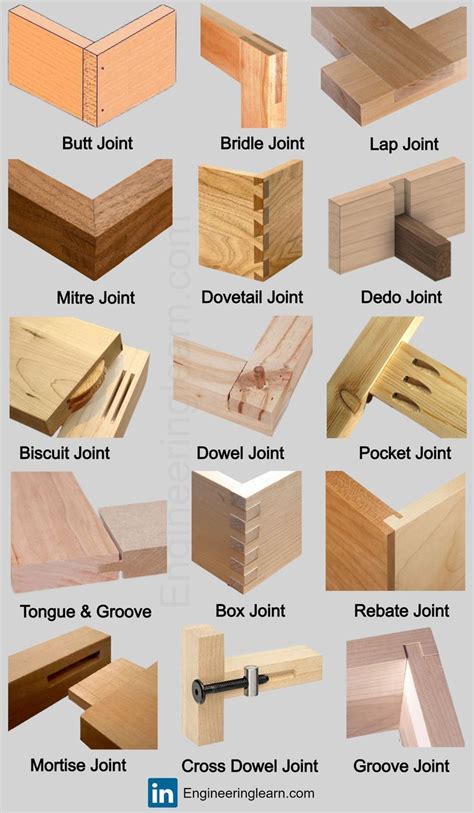

The Essential Tools for Achieving a Smooth and Flawless Finish

When it comes to achieving a polished and flawless finish on your woodworking projects, having the right tools is essential. These tools not only make the sanding process easier and more efficient but also ensure that you achieve a smooth and professional-looking result. In this section, we will explore the essential tools that every woodworker should have in their arsenal to achieve the desired finish.

- Sanding Blocks: These versatile tools are crucial for manual sanding. They come in various shapes and sizes, allowing you to reach different corners and contours of your woodwork.

- Power Sanders: Investing in a reliable power sander can significantly speed up the sanding process. There are different types of power sanders available, including orbital, belt, and random orbital sanders, each with their own advantages based on the task at hand.

- Sandpaper: Having a selection of sandpaper with varying grits is crucial for achieving a smooth finish. Coarse-grit sandpaper helps remove rough surfaces and imperfections, while fine-grit sandpaper is used for the final smoothing process.

- Sanding Discs and Belts: If you opt for power sanders, it's important to have a supply of sanding discs (for orbital sanders) or sanding belts (for belt sanders). These attachments are essential for achieving consistent and efficient sanding results.

- Dust Extractor: Sanding can produce a significant amount of dust, which not only affects the visibility but also poses health risks. A dust extractor or vacuum attachment helps keep the workspace clean and ensures that you can see your progress clearly.

- Sanding Sticks and Detail Sanding Tools: For intricate and hard-to-reach areas, sanding sticks and detail sanding tools are invaluable. These tools allow you to sand small corners, curves, and crevices with precision.

- Sanding Sealer: Applying a sanding sealer before sanding can help achieve a smoother and more even finish. This sealer fills in any minor imperfections in the wood, creating a level surface for sanding.

- Sanding Gloves and Safety Equipment: Safety should always be a priority when sanding. Wearing protective gloves, goggles, and a dust mask is crucial to protect yourself from flying debris and harmful dust particles.

By having these essential tools at your disposal, you can ensure that the sanding process is efficient, effective, and results in a flawless finish on your woodworking projects. Remember to use the appropriate tools and sandpaper grits based on the specific requirements of each project for the best outcome.

Sanding Techniques: Eliminating Scratches and Imperfections

In the pursuit of wooden perfection, an essential step is achieving a flawless surface. To accomplish this, learning effective sanding techniques is paramount. This section will delve into various methods and strategies to eliminate scratches, imperfections, and blemishes from wooden surfaces.

1. Smoothing Out Scratches: Scratches can mar the beauty of wood, but they can be remedied with the right sanding technique. Start by sanding the scratched area with a low-grit sandpaper, moving in the direction of the grain. Gradually increase the grit size as you progress, ensuring smooth sanding strokes. Finish by feathering the edges of the sanded area to seamlessly blend with the surrounding surface.

2. Removing Imperfections: Wood surfaces are prone to imperfections such as dents, nicks, and gouges. To repair these flaws, start by using a filler or putty that matches the wood's color and grain pattern. Apply the filler or putty to the affected area and use a putty knife to level it. Once dry, use sandpaper to sand the filled area gently, gradually increasing the grit size until the imperfection is no longer visible.

3. Avoiding Over-Sanding: Over-sanding can lead to an uneven surface or even damage the wood. To prevent this, ensure you have a clear understanding of your desired results before starting the sanding process. Begin with a coarse-grit sandpaper to remove any roughness or previous finishes. As you progress, transition to finer grits, taking care not to apply excessive pressure. Regularly assess the wooden surface during sanding to achieve the desired smoothness without going overboard.

4. Blending In Stain and Finish: When working with stained or finished wood, sanding imperfections can disrupt the color or finish. To seamlessly blend in the repaired area, start by lightly sanding the entire surface using a fine-grit sandpaper. This will create an even-textured base. Apply stain or finish to match the surrounding area, ensuring a uniform appearance across the wood. Allow sufficient drying time before proceeding with additional coats or protective finishes.

By mastering these sanding techniques, you can effectively remove scratches, imperfections, and other blemishes from wooden surfaces, bringing them one step closer to their full potential.

Understanding the Varieties of Timber and their Sanding Requirements

Cognizing the diverse categories of lumber and their corresponding sanding necessities is vital when pursuing a flawlessly sleek and refined finish. By comprehending the distinct characteristics of various wood types, one can employ the suitable techniques and equipment to accomplish optimal sanding outcomes.

Each species of timber possesses unique properties that influence its sanding requirements. The density, grain pattern, and hardness of wood impact the choice of abrasive materials and sanding method. For instance, softer woods typically necessitate gentler sanding and finer grits to prevent excessive material erasure, while harder woods may require more aggressive sanding to achieve the desired smoothness.

Furthermore, the presence of natural defects such as knots, resin pockets, or uneven grain can pose challenges during the sanding process. Understanding how to navigate these imperfections effectively is crucial in attaining a uniform and polished surface. Employing specialized techniques like filling, sealing, or using alternate sanding directions can help overcome these obstacles and enhance the final outcome.

Additionally, certain wood species possess distinct surface finishes, including oils or varnishes, which can affect the sanding procedure. Prior knowledge of the existing coating or treatment allows for appropriate adjustments in the sanding technique to ensure a cohesive and harmonious end result.

In conclusion, gaining a thorough understanding of the diverse characteristics and sanding requirements of different wood types is paramount for executing an impeccable sanding job. By tailoring the sanding method, abrasives, and techniques specifically to each wood species, one can achieve a superior finish and bring out the inherent beauty of the natural material.

Preparing Your Wood Surface for Sanding: Cleaning and Inspection

Before diving into the process of sanding your wood surface, it is crucial to first ensure that it is adequately prepared. This involves thorough cleaning and a meticulous inspection.

Proper cleaning is essential to remove any dirt, dust, or debris that may be present on the wood surface. This can be accomplished by using a soft cloth or brush to gently remove loose particles. For stubborn stains or sticky residue, a mild detergent solution can be applied sparingly and wiped away with a damp cloth. It is important to allow the wood surface to dry completely before proceeding.

Once the cleaning process is complete, a careful inspection should be conducted to identify any imperfections or damage that may require special attention during sanding. This can include cracks, knots, dents, or irregularities in the wood grain. It is recommended to run your hands along the surface to detect any rough spots or protruding edges that may need to be addressed.

Furthermore, it is important to check for any nails, staples, or other hardware that may be embedded in the wood. These can pose a risk during sanding and should be removed or properly secured before proceeding. Similarly, if there are any loose or damaged sections of the wood, repairs should be made prior to sanding to ensure a smooth and even surface.

By thoroughly cleaning and inspecting the wood surface before sanding, you can ensure that the sanding process is efficient and effective. This preparation step sets the foundation for achieving a beautifully sanded wood surface.

Time-Saving Strategies to Enhance Wood Sanding Efficiency

Streamlining the sanding process while still achieving exceptional results is an art every woodworker aspires to master. To effectively save time and increase efficiency, it is essential to adopt a series of well-thought-out techniques. This section will explore some pivotal strategies that enable you to optimize your wood sanding workflow without compromising on quality.

1. Prioritize Surface Preparation: Before commencing any sanding task, invest time in thorough surface preparation to ensure the wood is ready for sanding. This includes removing any existing coatings, contaminants, or imperfections that may hinder the sanding process. By starting with a clean canvas, you can minimize the amount of time spent sanding and achieve smoother, more refined results.

2. Choose the Right Sanding Grits: Carefully selecting the appropriate sandpaper grit sequence is paramount to efficient wood sanding. Begin with a coarser grit to eliminate larger imperfections, then gradually progress to finer grits to achieve a smoother finish. Avoid skipping grits, as this may lead to more time-consuming rework. Experiment with different grit combinations to discover the most effective sequence for each wood type and project.

3. Utilize Power Sanders: Incorporating power sanders into your workflow can significantly expedite the sanding process. Orbital sanders, belt sanders, and random orbital sanders are excellent tools that offer exceptional efficiency and precision. With proper technique and the right attachment, power sanders can effortlessly tackle large surface areas, saving you substantial time and effort.

4. Opt for Hand Sanding in Hard-to-Reach Areas: While power sanders excel in most situations, it is crucial to switch to hand sanding when dealing with intricate details or tight corners. Utilize sanding blocks, sponges, or folded sandpaper to effectively navigate challenging areas inaccessible to power tools. This targeted approach will ensure even sanding and maintain the overall efficiency of your workflow.

5. Dust Extraction for a Clean Environment: Integrating a reliable dust extraction system into your sanding setup is an indispensable time-saving measure. Dust accumulation not only hampers visibility and precision but also requires additional time for cleanup. Invest in a dust extractor or attach a shop vacuum to your power sander to efficiently capture dust particles, leaving your workspace clean and allowing you to focus on the task at hand.

By implementing these time-saving tips and techniques, you can enhance your wood sanding efficiency and accomplish pristine results in less time. Remember, efficiency does not equate to rushing. Take the necessary steps to prioritize surface preparation, choose the right tools and grits, and maintain a clean workspace. Striking a delicate balance between speed and precision will ultimately lead to a more enjoyable and productive wood sanding experience.

Avoiding Common Sanding Mistakes: Over-sanding and Under-sanding

When it comes to sanding wood, finding the balance between removing just enough material and preserving its natural beauty can be a challenging task. Two common mistakes that many people make during the sanding process are over-sanding and under-sanding.

Over-sanding, also known as excessive sanding, occurs when too much of the wood's surface is removed, resulting in a flat and lifeless appearance. This mistake can be particularly problematic when dealing with delicate and intricate woodwork, as it can easily strip away the intricate details and patterns that make the piece unique.

On the other hand, under-sanding, or insufficient sanding, can leave the wood rough, uneven, and with visible imperfections. This can be frustrating for those seeking a smooth and flawless finish, as it may require additional time and effort to correct the mistakes and achieve the desired result.

To avoid these common sanding mistakes, it is essential to approach the process with precision and care. Begin by assessing the wood's condition and identifying any areas that require more attention. Utilize a range of sandpaper grits, starting with a coarser grit to remove any rough patches or blemishes, and gradually working towards finer grits for a smooth finish.

It is crucial to pay attention to the pressure applied during sanding. Exerting too much force can lead to over-sanding, while too little pressure may result in under-sanding. Practice using steady and even pressure, allowing the sandpaper to do the work without exerting excessive force.

Additionally, periodically inspect the wood's surface during the sanding process to ensure that you are achieving the desired level of smoothness. A helpful technique is to run your hand lightly over the sanded area, feeling for any rough or uneven patches. This tactile method allows for a better understanding of the wood's texture and helps identify areas that need further attention.

In conclusion, avoiding common sanding mistakes, such as over-sanding and under-sanding, requires a careful and precise approach. By assessing the wood's condition, utilizing the appropriate sandpaper grits, applying consistent pressure, and periodically inspecting the surface, you can achieve a beautifully sanded piece of wood that highlights its natural beauty and craftsmanship.

The Significance of Dust Collection During the Sanding Process

Ensuring a clean and dust-free environment during the sanding process is crucial for several reasons. It not only promotes a healthier and safer workspace but also plays a significant role in achieving flawless results in your woodworking projects. Effective dust collection keeps the air clear from harmful particles, prevents respiratory issues, and avoids potential damage to your equipment and materials. In this section, we will explore the importance of implementing proper dust collection techniques during the sanding process and discuss the benefits it brings to your woodworking endeavors.

Promoting Health and Safety:

The accumulation of dust particles in the air can be hazardous to your respiratory system. Fine wood particles and debris, when inhaled, can lead to respiratory problems and allergic reactions. By implementing adequate dust collection measures, such as using a dust mask and efficient dust extraction systems, you minimize the risk of health issues and create a safer working environment.

Enhancing the End Results:

Dust and debris released during sanding can settle on the wood surface and impede the quality of your work. It can create blemishes, imperfections, and uneven finishes, making it difficult to achieve the desired results. With effective dust collection, you can ensure a clean sanding environment, which translates into smoother surfaces, better adherence of finishes, and flawlessly executed woodworking projects.

Preserving the Longevity of Equipment:

Proper dust collection not only benefits your health and the quality of your work but also plays a crucial role in prolonging the lifespan of your sanding equipment. Dust particles can cause abrasion, clog motors and moving parts, and lead to premature wear and tear. By implementing efficient dust collection systems, you reduce the accumulation of these particles on your equipment, ensuring their optimal performance and extending their lifespan.

Minimizing Clean-Up Efforts:

By proactively collecting dust during the sanding process, you minimize the amount of clean-up required afterward. An efficient dust collection system can significantly reduce the time and effort spent on removing dust particles from your workspace, allowing you to focus more on your woodworking projects. This not only saves valuable time but also keeps your workspace tidy and organized.

Overall, incorporating proper dust collection techniques during the sanding process is essential for maintaining a healthy and safe working environment, achieving impeccable woodworking results, preserving equipment longevity, and minimizing clean-up efforts. By prioritizing dust collection, you are able to create an ideal sanding setting that enhances the overall quality and enjoyment of your woodworking experience.

Mastering the Art of Achieving a Professional-Grade Finish with Sanding Sealer

When it comes to woodworking, one of the most essential steps in achieving a flawless final result is the application of sanding sealer. This innovative product not only helps to create a smooth and level surface but also serves as a protective layer that enhances the overall appearance of the wood. In this section, we will explore expert tips and techniques that will guide you towards achieving a professional-grade finish with sanding sealer.

Understanding the Purpose and Benefits of Sanding Sealer

Before diving into the techniques, it is important to understand the purpose and benefits of using sanding sealer. This product acts as a preparatory coat that fills in pores and seals the wood, ensuring a solid and uniform foundation for subsequent finishing coats. Additionally, sanding sealer enhances the natural beauty of the wood, providing a rich and lustrous appearance that is synonymous with professional craftsmanship.

Choosing the Right Sanding Sealer

Not all sanding sealers are created equal, and selecting the right one for your project is crucial. Consider the type of wood you are working with and the desired outcome. Different sealers offer varying levels of sheen, so take the time to experiment and find the perfect match for your project. Look for a high-quality sanding sealer that offers excellent adhesion, fast drying time, and easy sanding properties.

Preparing the Wood Surface

Before applying the sanding sealer, it is essential to properly prepare the wood surface to ensure optimal results. Begin by sanding the wood with progressively finer grit sandpaper to remove any imperfections, such as scratches or blemishes. Once the surface is smooth and free from debris, use a tack cloth to remove any dust particles that may interfere with the sealer's adhesion.

Applying the Sanding Sealer

When it comes to applying the sanding sealer, remember that less is more. Start by applying a thin and even coat using a high-quality brush, ensuring that you cover the entire surface area. Allow the sealer to dry according to the manufacturer's instructions, and then lightly sand the surface with fine-grit sandpaper. Repeat this process, applying additional coats as needed, until you achieve the desired level of coverage and smoothness.

Finishing Touches

Once the sanding sealer has fully cured, it's time to add the finishing touches to your masterpiece. Whether you choose to apply a clear topcoat, stain, or varnish, the sealed surface will provide a perfect canvas for enhancing the wood's natural beauty. Take your time and apply the final finishing coats with precision, allowing each layer to dry thoroughly before proceeding to the next.

Mastering the art of achieving a professional-grade finish with sanding sealer requires patience, attention to detail, and a deep understanding of the techniques involved. By following these expert tips, you will be well on your way to transforming ordinary wood into a work of art that will impress even the most discerning eye.

Enhancing the Natural Beauty: Adding Stains, Varnishes, and Polishes to Elevate the Wood

As wood artisans, we aim to bring out the inherent beauty of the materials we work with. To achieve this, we can employ various techniques that involve the application of stains, varnishes, and polishes. These finishing touches not only protect the wood but also enhance its aesthetic appeal, adding depth, richness, and a luxurious sheen.

| Stains | Varnishes | Polishes |

|---|---|---|

Stains offer a fantastic way to alter the wood's color, from deepening its tones to highlighting its natural variations. They seep into the wood's pores, enhancing its texture and creating a more uniform appearance. With a wide range of stain colors available, you can choose to bring out the warmth of red undertones or achieve a cooler, more modern look with gray or ashen hues. | Varnishes provide a protective layer that shields the wood from moisture, scratches, and UV damage. They come in various finishes, including matte, satin, and glossy, allowing you to achieve the desired level of sheen. By applying varnishes, you can not only preserve the wood's natural color but also enrich its nuances, adding a sophisticated and professional touch to your woodworking projects. | Polishes serve as the final step in the finishing process, enhancing the wood's beauty by adding a lustrous and smooth surface. They remove fine scratches, fill in small imperfections, and create a reflective shine that complements the overall appearance of the wood. With polishes, you can elevate the elegance of your woodwork, leaving a lasting impression on anyone who lays eyes on your exquisite creations. |

Each of these finishing elements requires a different application method and consideration for the type of wood you are working with. Understanding the characteristics of the wood and selecting the appropriate stains, varnishes, or polishes will enable you to achieve the best results. Experimentation and practice will further refine your skills, leading to breathtaking finishes that showcase the true beauty of the wood.

FAQ

What are some top tips for sanding wood?

There are several key tips for achieving a perfectly sanded wood surface. Firstly, always start with the right grit sandpaper depending on the type of wood and the level of imperfections. Next, ensure you have a smooth and even pressure while sanding, moving in the direction of the wood grain. Use a sanding block or a power sander for larger surfaces to maintain consistency. Additionally, take your time and be patient, as rushing the process can result in uneven sanding. Lastly, make sure to clean the wood thoroughly after sanding to remove any dust or debris before applying a finish.

Can you provide some techniques for sanding intricate woodwork?

When sanding intricate woodwork, it's important to be more delicate and meticulous. Start by selecting sandpaper with a fine grit to prevent damaging the delicate details. To reach small and difficult-to-reach areas, use sandpaper wrapped around a pencil or a small tool. Alternatively, foam sanding pads or rotary tools with sanding attachments can also be used. Take your time and work slowly, paying attention to detail. Lastly, use a soft-bristle brush or compressed air to remove any dust from the intricate areas after sanding.

What are the different types of sandpaper and when should they be used?

There are various types of sandpaper available, each with a different grit, which determines its coarseness. Coarse grit sandpapers (60-80 grit) are ideal for removing rough surfaces or paint from wood. Medium grit sandpapers (100-150 grit) are commonly used for general sanding and preparing the wood for a smooth finish. Fine grit sandpapers (180-220 grit) are used for achieving a smooth surface before applying a finish. Extra fine grit sandpapers (240-320 grit) are used for fine tuning and polishing the surface. It's important to choose the appropriate grit for the specific wood and the level of sanding required.

What are the potential risks or mistakes to avoid while sanding wood?

There are some common mistakes that should be avoided while sanding wood. One is using too much pressure, which can lead to uneven sanding and even gouging the wood. Another mistake is not sanding in the direction of the wood grain, as this can cause scratches and make the surface less smooth. It's also important to avoid staying in one spot for too long, as it can result in an uneven surface. Additionally, failing to clean the wood properly after sanding can affect the adhesion of the finish. Lastly, not wearing protective gear, such as a mask and safety goggles, can put one's health at risk due to the fine particles and dust generated during the sanding process.